At Aawadkrupa Plastomech Pvt. Ltd., we take pride in being a leading manufacturer and exporter of Roller Winder Machine. Our Roller Winder Machine are in high demand worldwide for their flexibility and efficiency. These machines are Important for winding various materials like textiles, paper, plastic films, and metal sheets onto rollers.

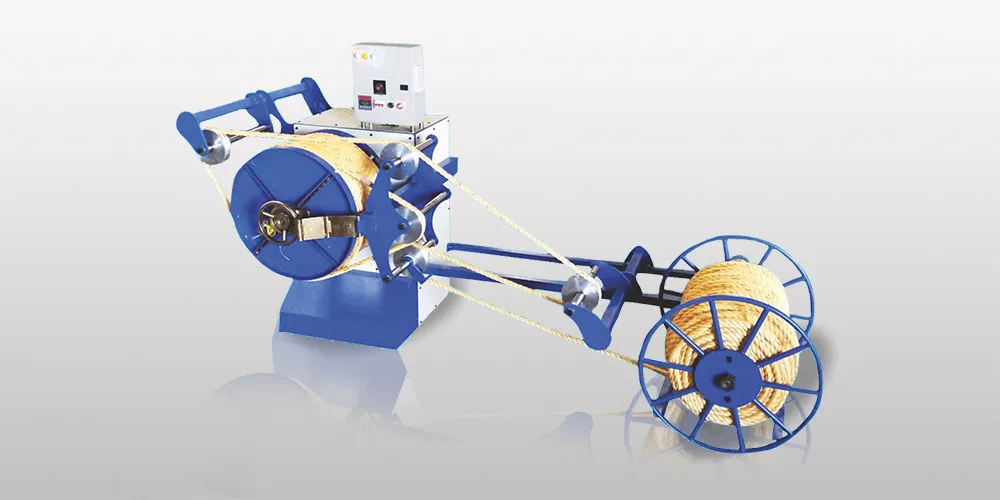

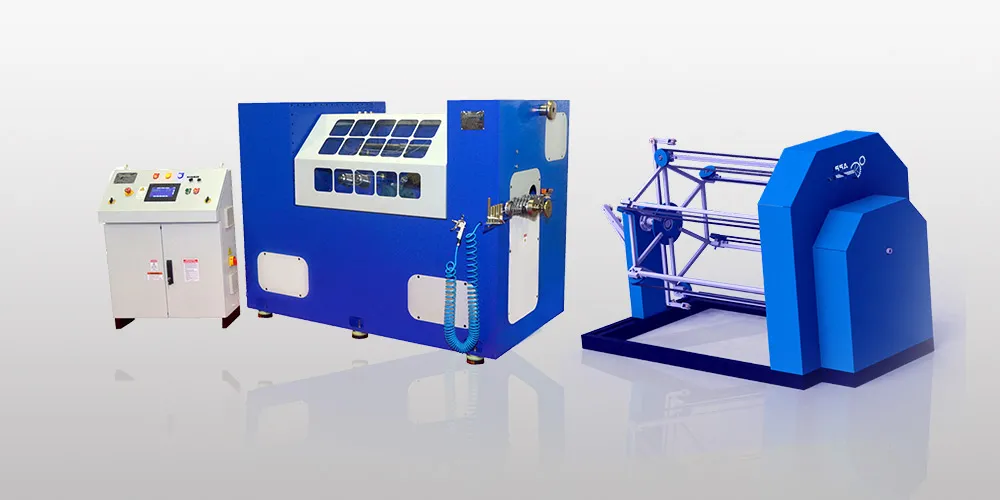

This machine ideal for industries such as packaging, printing, and textile production, our Roller Winder Machine simplify the winding process. They work by smoothly feeding the material through a series of rollers and then winding it onto the roller using a specialized mechanism. The machine includes feed rollers to guide the material, tension rollers to maintain proper tension, and a winding mechanism to neatly wind the material onto the roller.

With different types available, including single-roller, double-roller, and center-driven winders, our Roller Winder Machine source to a wide range of material weights and winding requirements. Whether you're working with light or heavy materials, our Roller Winder Machine are designed to deliver consistent and high-quality winding results every time. Elevate your production process with our reliable and efficient Roller Winder Machine from Aawadkrupa Plastomech Pvt. Ltd.