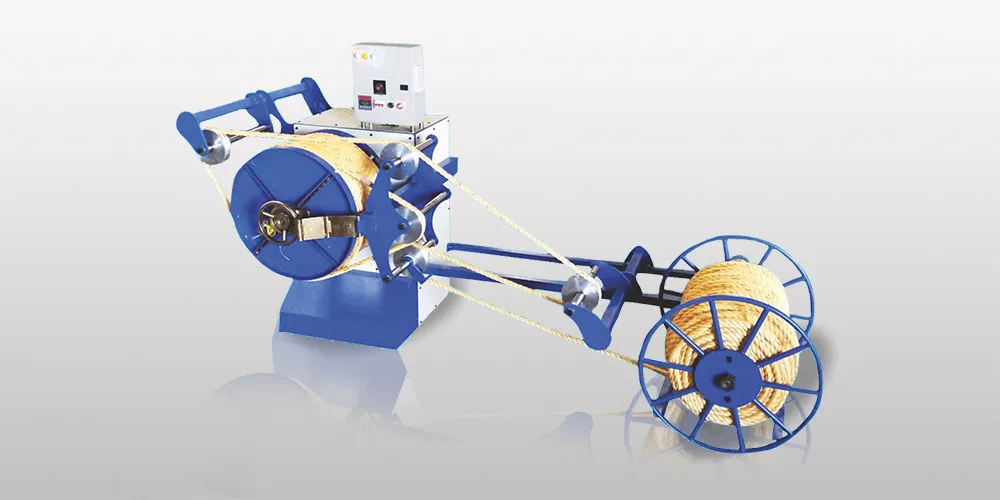

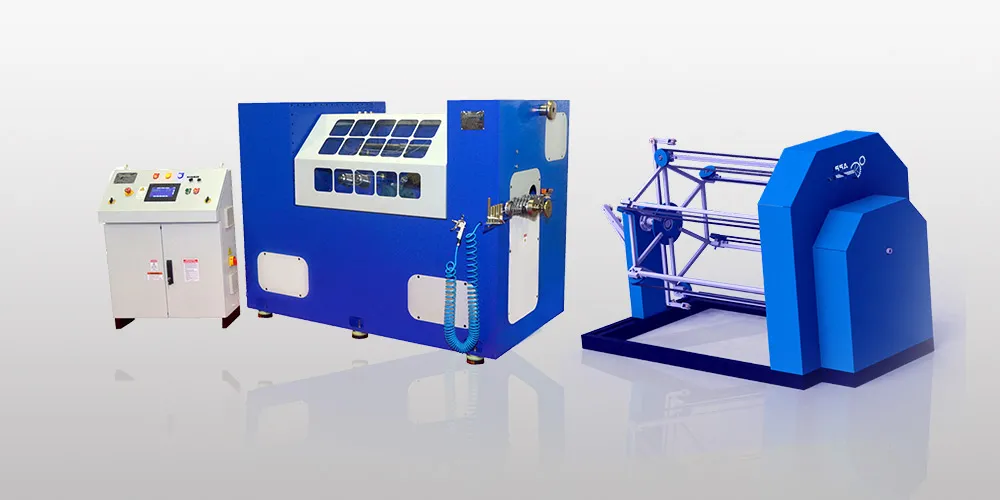

At Aawadkrupa Plastomech Pvt. Ltd., we take pride in being a leading manufacturer and exporter of Pineapple Winder Machine that are used worldwide. Our Pineapple Winder Machine is essential for the yarn winding process, which helps eliminate yarn faults like slubs, hairiness, and neps. By efficiently winding yarn, our machine ensures that spinner's bobbins are emptied for reuse, improving yarn quality for subsequent processes and boosting overall productivity.

Our Pineapple Winder Machine is designed for easy slowdown of yarn, smooth operations. It creates packages of the right size and shape to meet specific economic requirements, promoting cost-effectiveness. With a focus on avoiding excessive looseness or tightness in winding, our machine assurances optimal yarn packaging for superior results.

Your Trusted Aawadkrupa Plastomech Pvt. Ltd. for high-quality Pineapple Winder Machine that streamline yarn winding processes, upgrade yarn quality, and improve productivity in textile manufacturing operations worldwide.