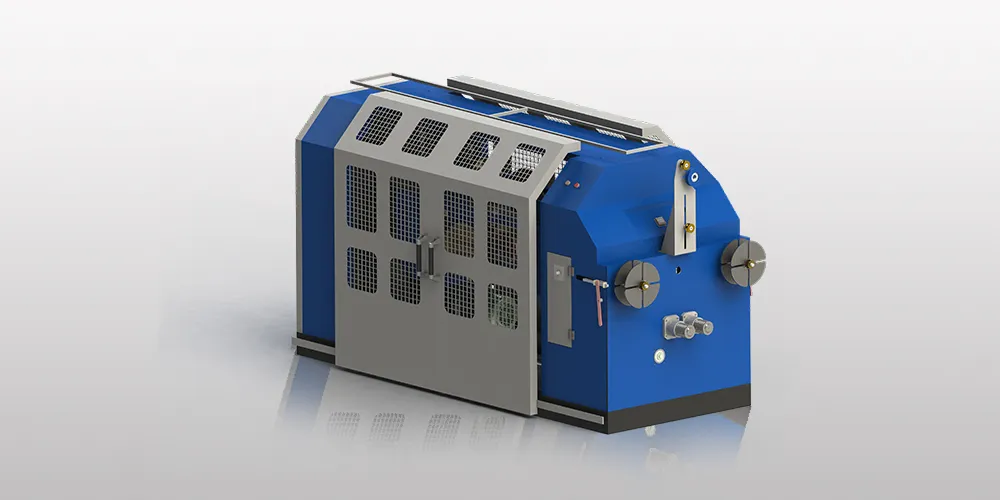

Aawadkrupa Plastomech Pvt. Ltd. leads the industry as a premier Manufacturer and Exporter of Crushing Dan line Extrusion Plant in worldwide. Our advanced Crushing Dan line Extrusion Plant is an innovative machine developing the recycling sector by converting plastic waste into reusable materials.

This advanced plant is engineered to crush, wash, and dry plastic waste before extruding it into pellets or granules, paving the way for the creation of new plastic products. Capable of processing various plastic waste types like PET bottles, HDPE films, and LDPE containers, our plant follows a meticulous process involving shredding, washing, drying, and extrusion.

By operating our Crushing Dan line Extrusion Plant, businesses can significantly reduce plastic pollution, conserve natural resources, and lower greenhouse gas emissions. Sustainability, our plant offers a sustainable solution by repurposing recycled plastic materials instead of virgin plastic, contributing to a cleaner environment and a greener future. Join us in our mission to transform plastic waste into a valuable resource with our advanced Crushing Dan line Extrusion Plant.