Aawadkrupa Plastomech Pvt. Ltd.'s advanced PP Non-Woven Fabric Machine. As a leading manufacturer and exporter, we deliver top-quality machinery worldwide to meet your non-woven fabric production needs.

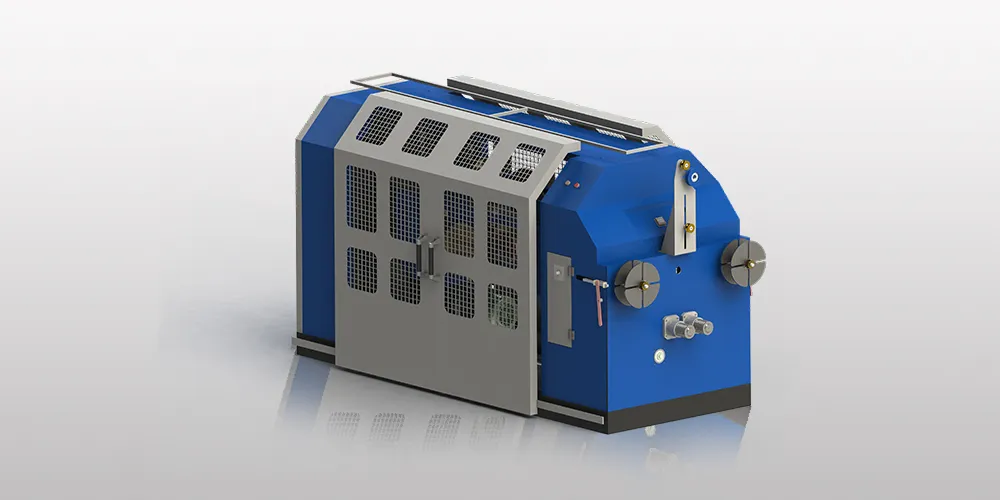

Our PP non-woven fabric machine is designed to create versatile fabric from polypropylene fibers, catering to industries like agriculture, medical, hygiene, packaging, and construction. The machine comprises key components like raw material feeding, melting and extrusion, web forming, calendaring, thermal bonding, winding, and slitting systems, a whole production process.

Crafting PP non-woven fabric involves melting PP granules, extruding them into a web through innovative technologies, and improving the fabric's strength through calendering and thermal bonding. The result? A lightweight, breathable, and water-resistant fabric that is cost-effective, customizable, and environmentally friendly due to its recyclable nature.

Invest in our PP Non-Woven Fabric Machine for efficient production of high-quality non-woven fabric that meets your specific industry requirements with ease.