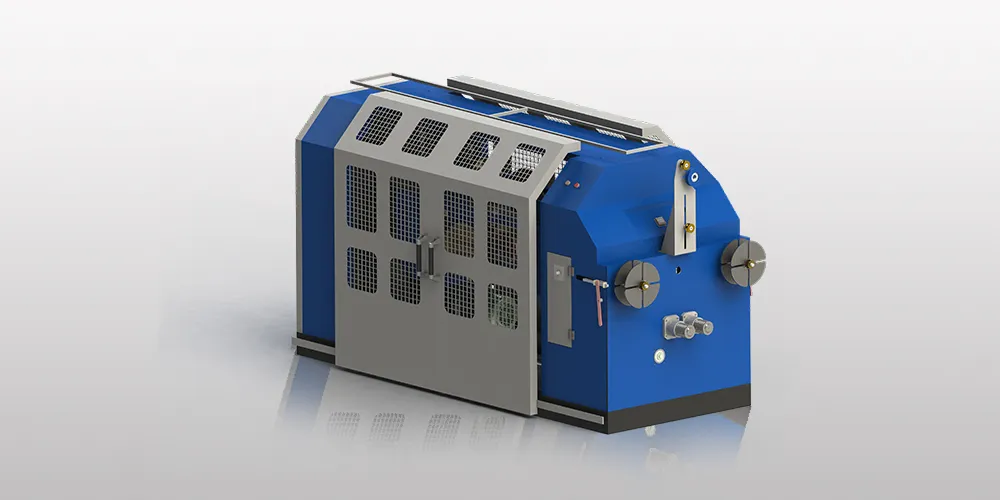

At Aawadkrupa Plastomech Pvt. Ltd., we are proud to offer our high-quality PP Tape Fibrillating Extrusion Plant, an innovative manufacturing unit that produces high-quality fibrillated yarn from polypropylene tapes. This innovative process involves melting and extruding polypropylene tapes to create a flat ribbon structure, which is then stretched and fibrillated to form a fine mesh of thin fibers. The resulting fibrillated yarn boasts exceptional strength, lightweight properties, and excellent resistance to chemicals and UV radiation.

Our PP Tape Fibrillating Extrusion Plant is designed for versatility, allowing for the production of various products such as bags, ropes, nets, geotextiles, carpet backing, and industrial fabrics. With its durable construction and superior abrasion resistance, fibrillated yarn manufactured using our plant is ideal for a wide range of industrial applications.

Your trusted Aawadkrupa Plastomech Pvt. Ltd. for all your PP Tape Fibrillating Extrusion Plant needs and experience the difference in efficiency, productivity, and profitability that our machinery can grow to your business.