High-Performance Plastic Net Making Machines for Diverse Industry Applications

Introduction

Plastic nets are widely used across various industries, including agriculture, construction, packaging, and safety. Their durability, lightweight nature, and resistance to environmental factors make them an essential material. To manufacture high-quality plastic nets, Aawadkrupa Plastomech, a leading manufacturer and exporter, provides state-of-the-art Plastic Net Making Machines that ensure precision, efficiency, and durability in production.

Machines Used in Plastic Net Manufacturing

-

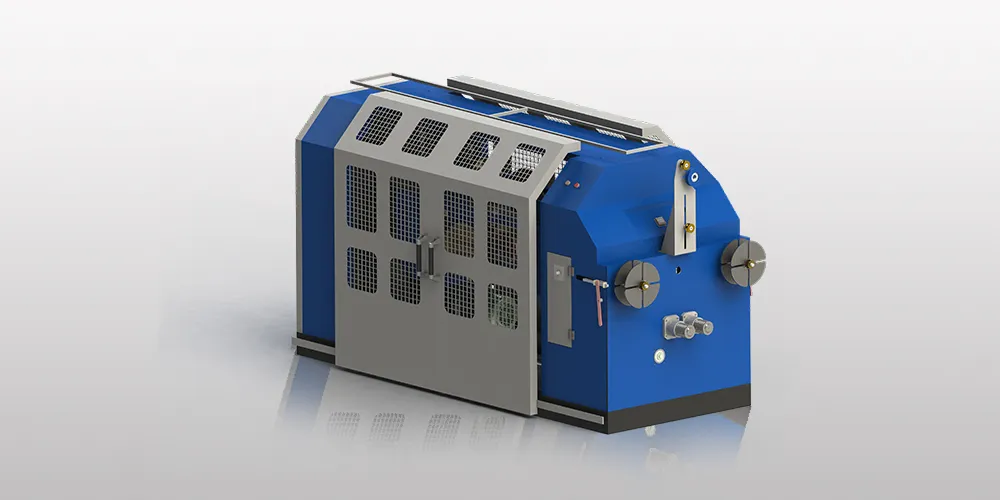

Monofilament Extrusion Plant

Plastic nets are often made using monofilament fibers, which provide strength and durability. The Monofilament Extrusion Plant by Aawadkrupa Plastomech plays a key role in this process by:

- Melting and extruding high-quality polymer filaments for net weaving

- Ensuring uniform thickness for consistent net strength

- Producing UV-resistant and weatherproof fibers for outdoor applications

-

PP Tape Fibrillating Extrusion Plant

For netting that requires woven or fibrillated structures, the PP Tape Fibrillating Extrusion Plant is essential. This machine:

- Extrudes and fibrillates PP tapes to create a mesh-like structure

- Enhances tensile strength for nets used in packaging, safety, and agriculture

- Customizes tape width and thickness for different net types

-

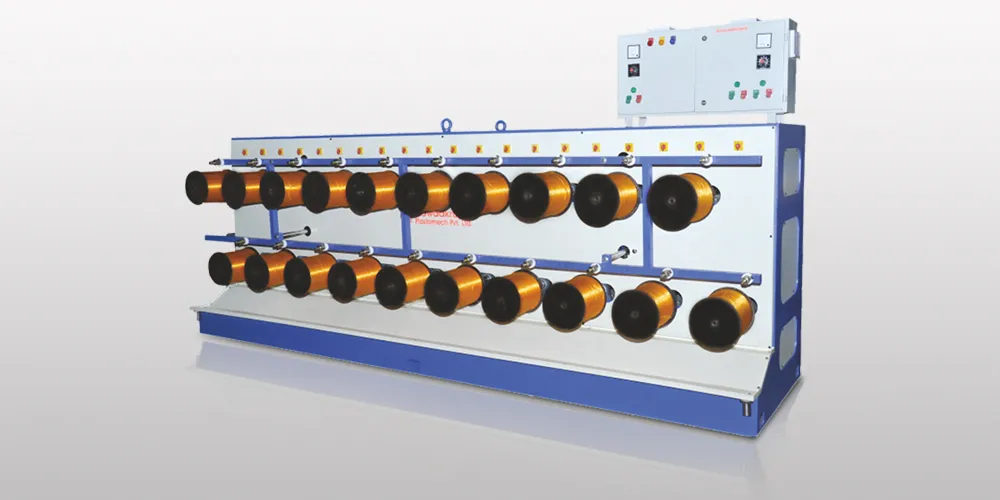

Bobbin Winder Machine

Once the extruded monofilament or PP tape is ready, it needs to be wound and prepared for net production. The Bobbin Winder Machine ensures:

- High-speed and automated winding of fibers or tapes

- Smooth and tension-controlled winding to prevent fiber breakage

- Easy handling for further net knitting or weaving processes

With these advanced machines, manufacturers can produce strong, flexible, and high-performance plastic nets tailored for various industries.

Fun Fact!

Did you know that plastic nets are inspired by nature? Spider webs have been studied by engineers to design strong, flexible, and lightweight nets for various applications, from fishing to construction safety barriers.

Key Features of Aawadkrupa Plastomech’s Plastic Net Making Machines

High-Speed Extrusion

Efficient production for large-scale output

Precision Engineering

Ensures uniform fiber thickness and strength

Robust Machinery

Durable equipment for long-term use

Energy Efficient

Optimized power consumption for cost savings

Customization Options

Different net types, mesh sizes, and colors available

Automated Controls

User-friendly and seamless operation

Global Export Standards

Compliance with international quality requirements

Applications of Plastic Nets

Plastic nets made using Aawadkrupa Plastomech’s machines are used in various industries:

- Agriculture & Farming: Used for shade nets, plant protection, and poultry enclosures

- Construction & Safety : Barrier nets, scaffolding safety nets, and fencing

- Packaging & Transport : Mesh bags for fruits, vegetables, and industrial packaging

- Fishing & Aquaculture : Durable nets for fish farming and marine applications

- Household & Sports : Used for garden fencing, mosquito nets, and sports nets

Why Choose Aawadkrupa Plastomech?

As a trusted manufacturer and exporter, Aawadkrupa Plastomech provides high-performance Plastic Net Making Machines with:

Innovative technology for precision and efficiency

Superior material processing for durable net production

Customization options to meet diverse industry requirements

Proven expertise and global exports for reliable service

By integrating the Monofilament Extrusion Plant, PP Tape Fibrillating Extrusion Plant, and Bobbin Winder Machine, manufacturers can achieve cost-effective, high-quality, and efficient plastic net production.

Conclusion

Plastic nets are essential across multiple industries, and Aawadkrupa Plastomech’s advanced machinery ensures that manufacturers can produce them efficiently and with superior quality. Whether for agriculture, safety, packaging, or fishing, these machines provide exceptional output with precision and durability.

For more information about our products and services, please call us at +91 9510186014 or mail us at info@akiropes.com. Discover how we can help you revolutionize your production processes with cutting-edge extrusion technology.