High-Performance PET Strap Extrusion Machines for Strong and Reliable Strapping

Introduction

In industries like packaging, logistics, and construction, Polyethylene Terephthalate (PET) straps play a crucial role in securing heavy loads, bundling materials, and ensuring safe transportation. As a strong, durable, and eco-friendly alternative to steel straps, PET straps have gained immense popularity.

To meet the increasing demand for high-quality PET straps, Aawadkrupa Plastomech offers an advanced PET Strap Extrusion Machine, ensuring precision, efficiency, and high-output production for manufacturers worldwide.

Machines Used in PET Strap Manufacturing

-

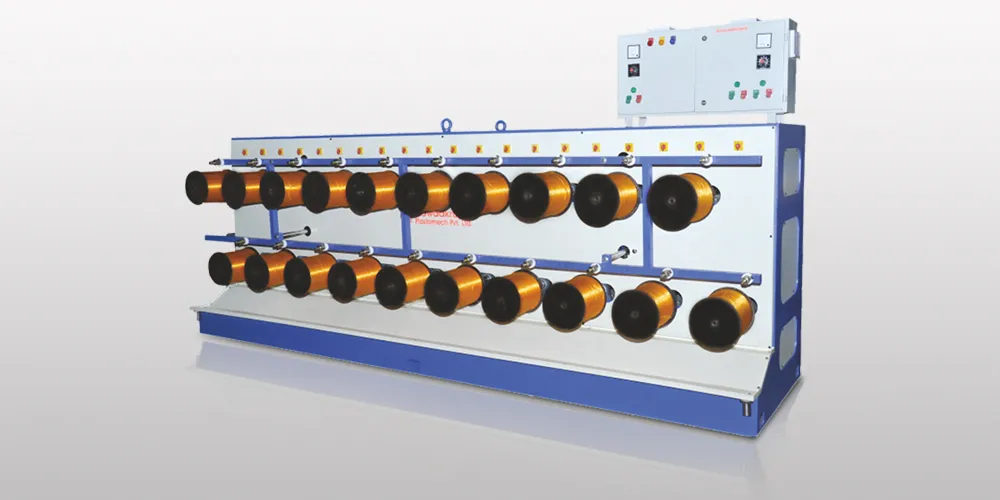

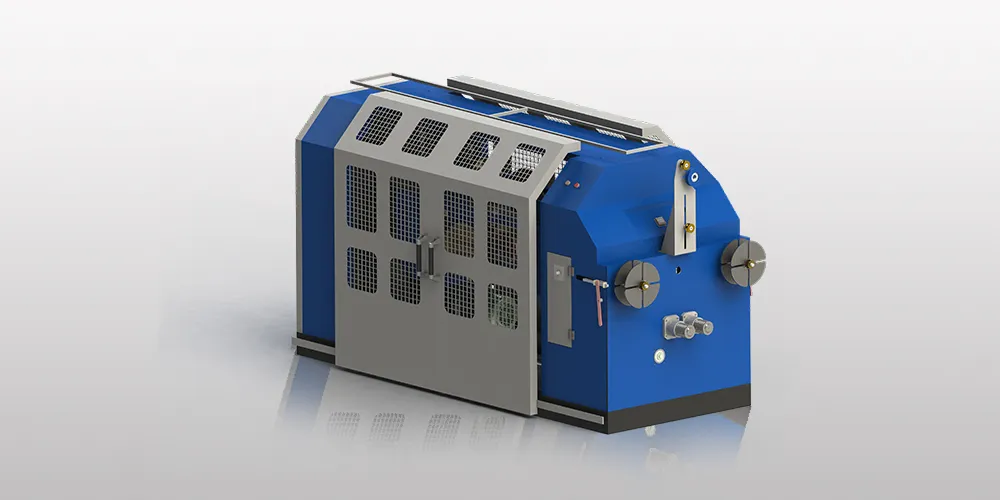

PET Strap Extrusion Machine

The PET Strap Extrusion Machine is designed to produce high-strength PET straps from recycled or virgin PET materials. Aawadkrupa Plastomech’s PET Strap Extrusion Machine offers:

- High-speed extrusion for large-scale production

- Uniform strap thickness for consistent strength and durability

- Advanced cooling system to maintain strap flexibility and quality

- Energy-efficient operation, reducing production costs

This machine is widely used in packaging industries, logistics companies, construction sectors, and manufacturing units, ensuring strong and reliable strapping solutions.

Fun Fact!

Did you know that PET straps can withstand up to five times their own weight? This makes them a strong and cost-effective alternative to metal straps in industries that require heavy-duty load securing.

Key Features of Aawadkrupa Plastomech’s PET Strap Extrusion Machine

High-Speed Production

Enables mass production of PET straps

Precision Control

Ensures uniform thickness and consistent strap quality

Eco-Friendly Technology

Uses recycled PET materials for sustainable production

Durable Construction

Designed for long-term industrial use

Automated Operation

User-friendly controls for seamless performance

Cost-Efficient

Reduces material waste and energy consumption

Applications of PET Straps

The PET Strap Extrusion Machine by Aawadkrupa Plastomech is used to produce high-strength PET straps for multiple applications, including:

- Packaging Industry: Used for bundling boxes, pallets, and cartons

- Logistics & Warehousing : Ensures safe transportation of goods

- Construction & Building Materials : Secures bricks, tiles, and heavy loads

- Textile & Paper Industry : Keeps fabric and paper rolls intact

- Automotive & Electronics : Protects sensitive equipment during transit

Why Choose Aawadkrupa Plastomech?

As a leading manufacturer and exporter, Aawadkrupa Plastomech provides state-of-the-art PET Strap Extrusion Machines with:

Cutting-edge extrusion technology for precise and efficient production

Sustainable manufacturing solutions, using recycled PET materials

Customizable machine configurations to meet industry-specific needs

Proven expertise in global exports, ensuring top-tier quality and service

With Aawadkrupa Plastomech’s PET Strap Extrusion Machine, manufacturers can boost their production efficiency, reduce costs, and contribute to sustainable packaging solutions.

Conclusion

The demand for durable, eco-friendly, and cost-effective strapping solutions is growing, and Aawadkrupa Plastomech’s PET Strap Extrusion Machine ensures that manufacturers can produce high-quality PET straps with maximum efficiency. Whether for packaging, logistics, or industrial applications, this machine guarantees superior output and long-term reliability.

For more information about our products and services, please call us at +91 9510186014 or mail us at info@akiropes.com. Discover how we can help you revolutionize your production processes with cutting-edge extrusion technology.