Introduction

Paper is one of the most essential materials used worldwide in various industries, including education, packaging, printing, and manufacturing. It plays a significant role in daily life, from books and newspapers to paper bags and industrial packaging. The demand for high-quality paper continues to rise as industries shift towards sustainable and eco-friendly alternatives to plastic.

Uses of Paper

Paper is an incredibly versatile material used for different purposes across industries. Some of the key applications of paper include:

- Printing & Writing: Books, newspapers, notebooks, and office documents are all dependent on high-quality paper.

- Packaging: The packaging industry relies heavily on paper for making boxes, cartons, and paper bags.

- Hygiene Products: Tissue paper, napkins, and other disposable hygiene products are made from specialized paper.

- Industrial Applications: Paper is widely used in laminations, wrapping, and protective layering in various industries.

- Eco-friendly Solutions: Many companies are replacing plastic with paper for an environmentally friendly alternative.

The Need for High-Quality Paper in Manufacturing

Industries like printing, packaging, and textiles rely heavily on high-quality paper. Consistency in thickness, texture, and strength is critical for manufacturers to maintain efficiency and product reliability. Paper winding is an important step in the manufacturing process that ensures the material is neatly rolled for further processing. Without efficient paper winding, production can face material wastage, inefficiency, and increased costs.

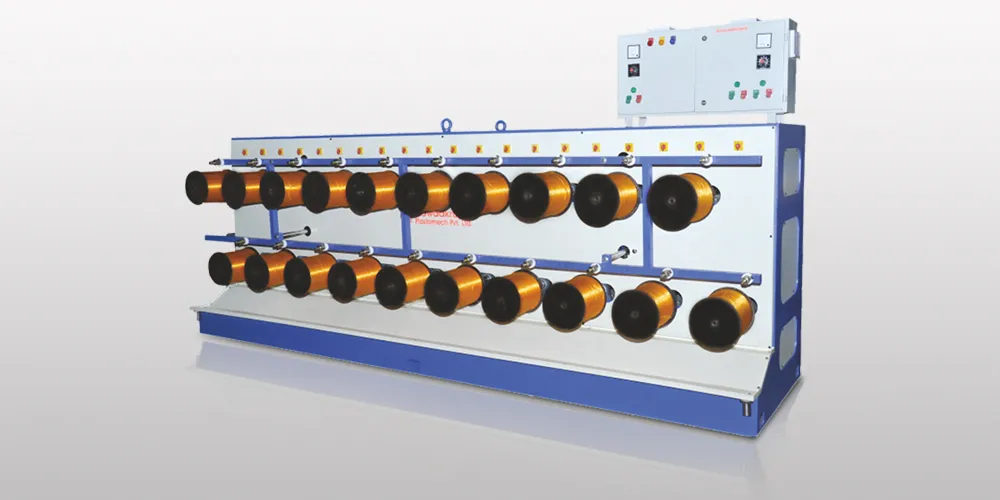

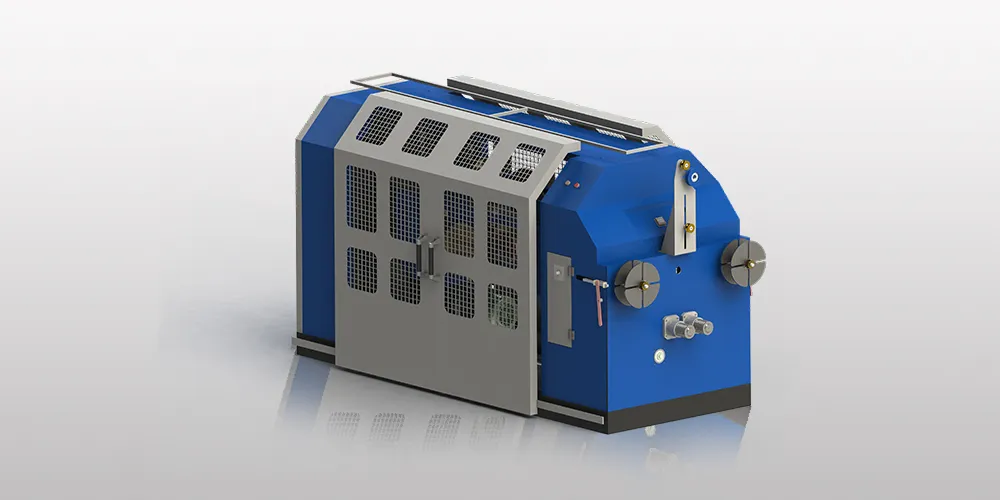

The Machine Used for Paper Winding – Roller Winder Machine

A Roller Winder Machine is essential in the paper industry as it helps wind large sheets of paper onto rolls for further processing. This machine improves efficiency, reduces labor costs, and enhances precision, making it a necessity for manufacturers.

The Roller Winder Machine from Aawadkrupa Plastomech Pvt. Ltd. is a high-performance machine designed for paper winding. Some of its most notable features include:

Precision Winding

The machine ensures smooth and even winding, reducing material wastage

High-Speed Operation

Capable of handling large volumes of paper efficiently

Adjustable Tension Control

Helps in maintaining the desired tension to prevent wrinkles or breakage

Versatile Applications

Can be used for paper, textiles, plastic films, and metal sheets

User-Friendly Design

Easy to operate and maintain, minimizing downtime in production

How the Roller Winder Machine Works

The Roller Winder Machine works by feeding paper through a series of rollers, maintaining precise tension, and neatly winding it onto a roller. Here’s how it functions:

- Feed Rollers: Guide the paper into the machine smoothly

- Tension Rollers: Maintain proper tension to ensure even and uniform winding

- Winding Mechanism: Rolls the paper onto a large roller without creases or damage

Why is a Roller Winder Machine Important for Paper Manufacturers?

Manufacturers specializing in paper winding need high-performance Roller Winder Machines to optimize their production process. Here’s why:

Increased Efficiency

Automating the paper winding process significantly improves production speed

Cost Reduction

Reduces labor and material wastage, lowering overall costs

High Precision

Ensures that the paper is wound evenly without wrinkles or misalignment

Scalability

Ideal for small, medium, and large-scale manufacturing units

Industries That Benefit from Roller Winder Machines

The Roller Winder Machine is widely used across various industries, including:

Packaging Industry

Printing Industry

Textile Industry

Industrial Manufacturing

Why Choose Aawadkrupa Plastomech Pvt. Ltd.?

Aawadkrupa Plastomech Pvt. Ltd. Is a leading manufacturer & Exporter of Roller Winder Machine. we specialize in designing and manufacturing top-quality Roller Winder Machines that cater to industries worldwide. Our machines are known for their durability, efficiency, and advanced technology.

Our expertise in paper winding solutions ensures that manufacturers get high-performance machines that improve efficiency, reduce operational costs, and deliver precise results. Whether you're in the packaging, printing, or textile industry, our Roller Winder Machines offer unparalleled reliability and quality.

Conclusion

The demand for high-quality paper continues to grow as industries seek sustainable and efficient alternatives to plastic. The Roller Winder Machine plays a critical role in paper winding, ensuring smooth, uniform, and efficient processing for various applications.

Investing in a Roller Winder Machine from Aawadkrupa Plastomech Pvt. Ltd. provide high efficiency, cost savings, and superior performance in paper manufacturing. Our advanced winding technology makes us the preferred choice for businesses worldwide.

For more information about our Roller Winder Machines, feel free to contact us today! Call us at +91 9510186014 or email us at info@akiropes.com to learn how we can help your business with high-quality paper winding solutions.