Fibrillated yarn is a versatile and durable synthetic material used across various industries for its lightweight, high strength, and resistance to chemicals and UV radiation. This specialized yarn is produced from polypropylene (PP) tapes, which undergo a unique fibrillation process to create a fine mesh of interconnected fibers.

As industries shift towards stronger, cost-effective, and durable materials, fibrillated yarn has become a preferred choice in packaging, agriculture, textiles, construction, and geotextiles. To meet the growing demand, manufacturers require advanced machinery that can efficiently produce high-quality fibrillated yarn with precision and consistency.

Uses of Fibrillated Yarn

Fibrillated yarn is widely used in various applications due to its durability, flexibility, and cost-effectiveness. Here are some of its primary uses:

-

Packaging Industry:

- Used in woven bags, shopping bags, and bulk bags for added strength and durability

- Helps reinforce industrial sacks used for cement, chemicals, and agricultural produce

-

Rope and Net Manufacturing:

- Fibrillated yarn is an essential component in ropemaking, providing better grip and strength

- Used in fishing nets, sports nets, and agricultural nets for enhanced durability and long-lasting performance

-

Agriculture and Horticulture:

- Used in shade nets, greenhouse coverings, and crop protection fabrics to shield plants from extreme weather conditions

- Provides soil stabilization and erosion control in farming applications

-

Carpet and Textile Industry:

- Used in carpet backing and reinforcement fabrics to increase the durability and lifespan of carpets

- Used in industrial and geotextile fabrics for strength and flexibility

-

Construction and Infrastructure:

- Utilized in geotextiles and reinforcement fabrics for roads, drainage, and erosion control

- Used in concrete reinforcements and industrial linings to improve material strength

The Need for High-Quality Fibrillated Yarn in Manufacturing

With industries demanding stronger and more durable synthetic yarns, fibrillated yarn has become a crucial component in industrial and commercial applications. Traditional yarns cannot match the tensile strength, longevity, and resistance to wear and tear that fibrillated yarn provides.

To manufacture high-quality fibrillated yarn, businesses need an efficient and reliable production process. This is where the PP Tape Fibrillating Extrusion Plant plays a vital role in ensuring high output, minimal waste, and superior product quality.

The Machine Used for Fibrillated Yarn Production – PP Tape Fibrillating Extrusion Plant

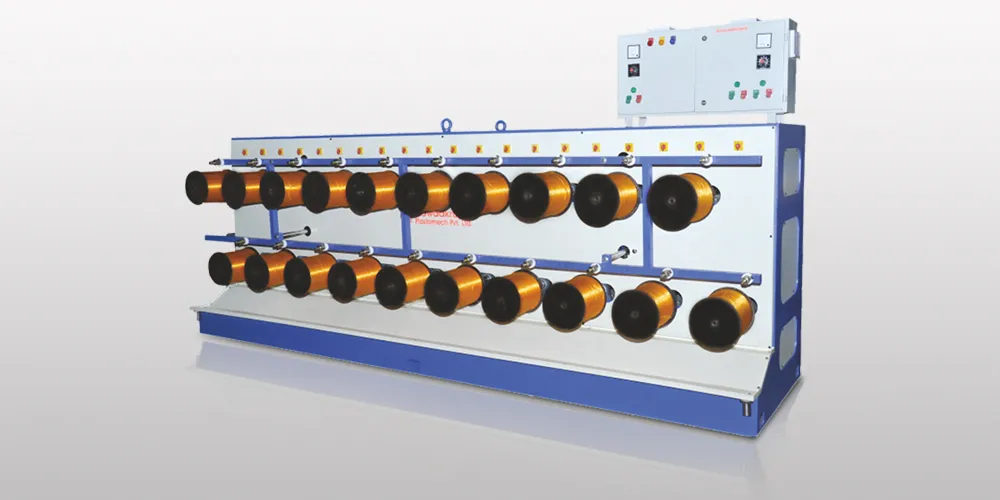

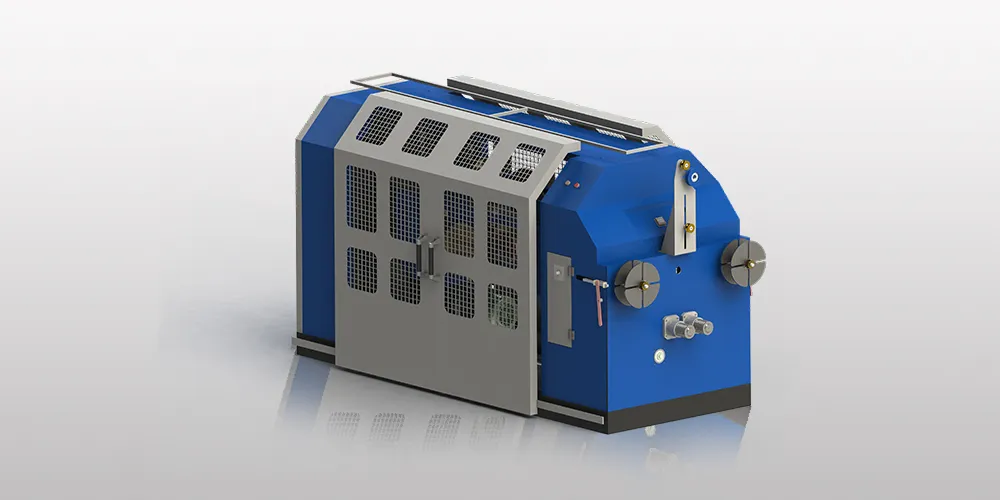

A PP Tape Fibrillating Extrusion Plant is an advanced manufacturing unit designed to produce high-quality fibrillated yarn from polypropylene tapes. This fully automated system melts and extrudes PP tapes into flat ribbon-like structures, which are then stretched and fibrillated to create a fine mesh of interconnected fibers.

The PP Tape Fibrillating Extrusion Plant from Aawadkrupa Plastomech Pvt. Ltd. is designed with cutting-edge technology to ensure high-speed production, precision, and efficiency. Here are some of its standout features:

Advanced Extrusion Technology

Ensures uniform PP tape extrusion for consistent fibrillated yarn production

High-Speed Production

Capable of handling large-scale yarn manufacturing with minimal downtime

Precision Fibrillation Mechanism

Creates a fine, evenly distributed mesh of fibers to enhance strength and flexibility

Energy-Efficient Design

Operates with low power consumption, reducing operational costs

User-Friendly Control System

Equipped with an intelligent control panel for easy operation and monitoring

Versatile Applications

Suitable for manufacturing ropes, nets, bags, geotextiles, carpet backing, and industrial fabrics

How the PP Tape Fibrillating Extrusion Plant Works

The PP Tape Fibrillating Extrusion Plant follows a systematic process to convert polypropylene tapes into fibrillated yarn. Here’s how it works:

- Raw Material Feeding: Polypropylene (PP) granules are fed into the extruder for melting

- Extrusion & Taping: The molten PP is extruded into thin tape-like ribbons

- Stretching Process: The PP tapes are stretched to achieve the desired tensile strength

- Fibrillation Mechanism: The stretched tapes are fibrillated using specialized blades, creating a mesh of thin fibers

Why is a PP Tape Fibrillating Extrusion Plant Important for Manufacturers?

Manufacturers specializing in fibrillated yarn production need a high-speed, precision-based machine to meet growing industrial demands. Investing in a PP Tape Fibrillating Extrusion Plant provides several advantages:

Enhanced Productivity

Produces large volumes of fibrillated yarn at high speed

Superior Product Quality

Ensures uniform fibrillation and consistent yarn strength

Reduced Waste & Cost Efficiency

Minimizes material wastage while optimizing raw material usage

Energy & Labor Savings

Automated production reduces the need for manual labor and lowers energy consumption

Versatility

Can be used for multiple industrial applications, including packaging, textiles, and agriculture

Industries That Benefit from the PP Tape Fibrillating Extrusion Plant

The PP Tape Fibrillating Extrusion Plant is widely used in various industries, including:

Packaging & Bag Manufacturing

Rope & Net Production

Carpet & Textile Industry

Agriculture & Horticulture

Geotextiles & Construction

Why Choose Aawadkrupa Plastomech Pvt. Ltd.?

At Aawadkrupa Plastomech Pvt. Ltd., we specialize in designing and manufacturing state-of-the-art PP Tape Fibrillating Extrusion Plants for businesses worldwide. Our machines are known for their high efficiency, durability, and innovative technology, making them the ideal choice for fibrillated yarn manufacturers.

With a commitment to quality and innovation, we provide cutting-edge solutions that enhance production efficiency and product reliability. Whether you operate in the packaging, textile, or construction industry, our PP Tape Fibrillating Extrusion Plant guarantees superior output with minimal operational costs.

Conclusion

The demand for high-quality fibrillated yarn is increasing rapidly across multiple industries. To meet this demand, manufacturers need efficient, automated, and high-speed machinery that can produce strong, lightweight, and cost-effective fibrillated yarn.

Investing in a PP Tape Fibrillating Extrusion Plant from Aawadkrupa Plastomech Pvt. Ltd. guarantees precision, efficiency, and high productivity, helping businesses maximize profitability and stay ahead of market competition. Our advanced technology and expertise make us the preferred choice for fibrillated yarn production solutions.

Looking for the best fibrillated yarn manufacturing solutions? Contact us today! Call us at +91 9510186014 or email us at info@akiropes.com to discover how our PP Tape Fibrillating Extrusion Plant can revolutionize your production process.