High-Quality Brush Broom Filament Yarn Making Machines for Durable Bristles

Introduction

Brushes and brooms are an essential part of everyday cleaning, industrial applications, and specialized sectors like street sweeping, car washing, and household cleaning. The quality of filament yarn used in these products determines their durability, flexibility, and efficiency. To meet the global demand for high-quality broom and brush filaments, Aawadkrupa Plastomech offers advanced Brush Broom Filament Yarn Making Machines, ensuring precision, efficiency, and superior output.

Machines Used in Plastic Net Manufacturing

-

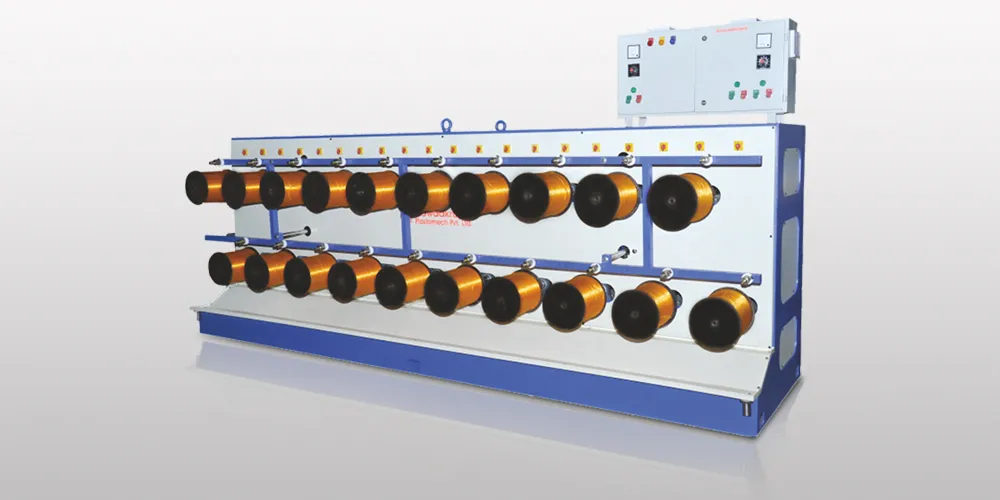

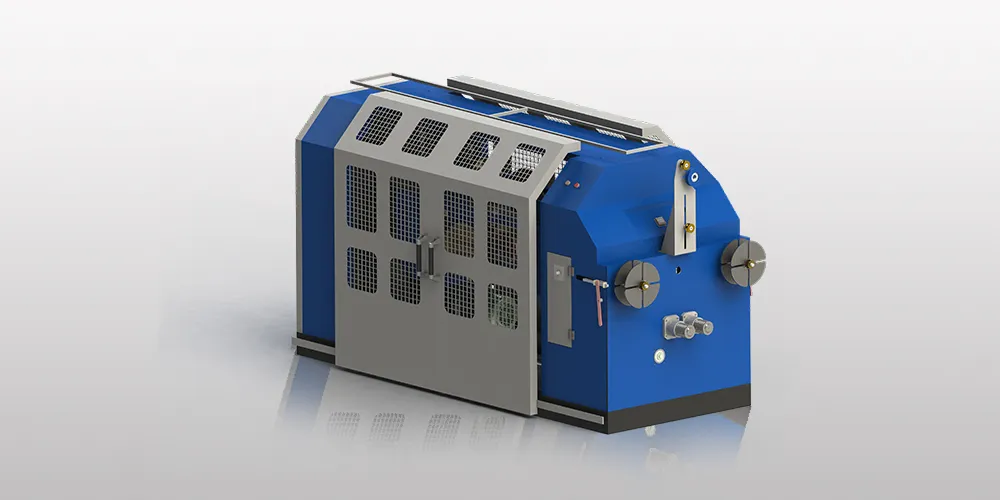

PET Monofilament Extrusion Plant

Polyethylene Terephthalate (PET) monofilaments are widely used for making brush and broom filaments due to their strength, flexibility, and resistance to wear and chemicals. The PET Monofilament Extrusion Plant by Aawadkrupa Plastomech plays a crucial role in the manufacturing process by:

- Melting and extruding PET granules into high-strength filaments

- Ensuring uniform filament thickness for consistent bristle performance

- Producing UV-resistant and durable fibers suitable for indoor and outdoor use

This machine is designed for high-speed production, ensuring that manufacturers can meet large-scale demands while maintaining quality.

Fun Fact!

Did you know that ancient Egyptians were among the first to use brooms made of natural fibers like twigs and grass? Today, synthetic filaments have replaced natural materials in modern brooms, offering longer-lasting and more efficient cleaning performance.

Key Features of Aawadkrupa Plastomech’s Brush Broom Filament Yarn Making Machines

High-Speed Extrusion

Efficient production of large quantities of filament yarn

Precision Engineering

Ensures uniform filament thickness and quality

Robust Machinery

Durable equipment for long-term use

Energy Efficient

Optimized power consumption for cost savings

Customization Options

Different filament thickness, colors, and textures available

Automated Controls

User-friendly and seamless operation

Global Export Standards

Compliance with international quality requirements

Applications of Brush Broom Filaments

Filaments produced using Aawadkrupa Plastomech’s PET Monofilament Extrusion Plant are used in a variety of applications, including:

- Household Cleaning Brushes: Soft yet durable bristles for sweeping and scrubbing

- Industrial Brushes : Used in machinery cleaning, metal finishing, and polishing

- Street Sweeping Brooms : Strong, stiff bristles designed to clean roads and rough surfaces

- Car Washing Brushes : Gentle yet effective filaments for cleaning vehicles

- Paintbrushes : PET filaments are widely used for synthetic paintbrush bristles

Why Choose Aawadkrupa Plastomech?

As a trusted manufacturer and exporter, Aawadkrupa Plastomech provides high-performance Brush Broom Filament Yarn Making Machines with:

Cutting-edge technology for efficient filament extrusion

Superior material processing for durable and flexible filaments

Customization options to meet industry-specific needs

Proven expertise and global exports for reliable service

By integrating the PET Monofilament Extrusion Plant, manufacturers can produce high-quality brush and broom filaments that meet global standards for durability and performance.

Conclusion

The demand for durable and efficient brush and broom filaments is ever-growing, and Aawadkrupa Plastomech’s advanced PET Monofilament Extrusion Plant ensures that manufacturers can produce high-quality synthetic filaments with precision and efficiency. Whether for household, industrial, or specialized applications, these machines deliver exceptional output and long-term reliability.

For more information about our products and services, please call us at +91 9510186014 or mail us at info@akiropes.com. Discover how we can help you revolutionize your production processes with cutting-edge extrusion technology.