Advanced Artificial Grass Making Machines for High-Quality Turf Production

Introduction

The demand for artificial grass has grown significantly across various industries, including landscaping, sports, and home décor. As an eco-friendly and low-maintenance alternative to natural grass, artificial turf is widely used for playgrounds, stadiums, and residential lawns. To meet this rising demand, Aawadkrupa Plastomech has designed state-of-the-art machinery ensuring high-quality synthetic turf production with efficiency and precision.

Machines Used in Artificial Grass Manufacturing

-

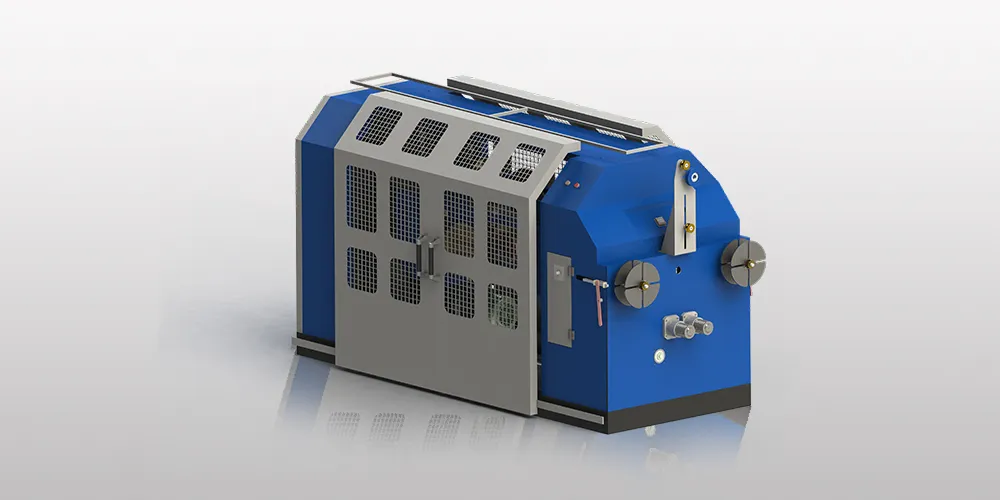

Monofilament Extrusion Machine

Artificial grass is made using monofilament fibers, which mimic the look and feel of natural grass. The Monofilament Extrusion Machine from Aawadkrupa Plastomech is crucial in this process. It melts and extrudes high-quality polymer-based filaments, ensuring:

- Uniform thickness and strength for a durable final product

- UV resistance and weatherproof properties for long-lasting turf

- Customizable filament designs for different turf textures and colors

-

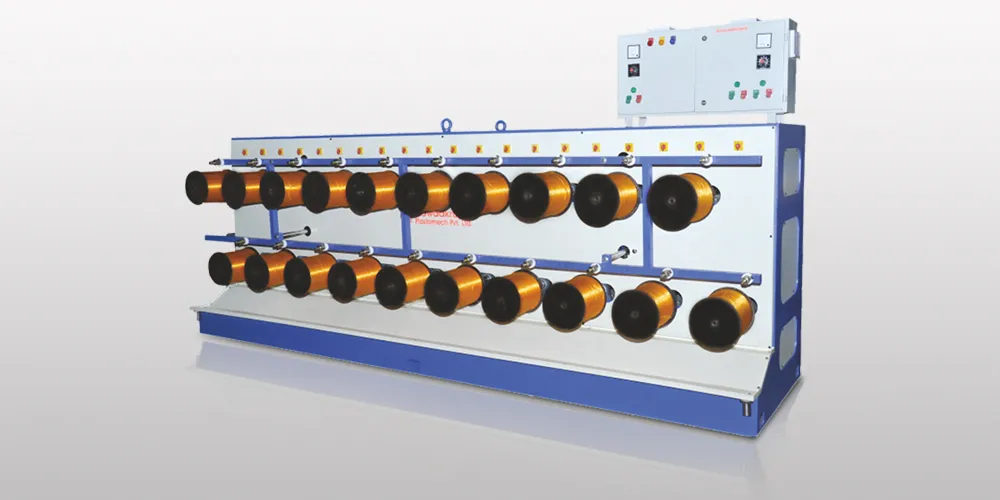

Ring Twister Machine

Once the filaments are extruded, they need to be twisted and strengthened. The Ring Twister Machine is used to twist multiple strands of monofilament together, creating a stronger and more resilient yarn for artificial grass. This process enhances:

- Durability and flexibility for long-term use

- Tensile strength to withstand heavy foot traffic

- Better resilience for sports and landscaping applications

Aawadkrupa Plastomech’s cutting-edge technology ensures precision in twisting and extrusion, leading to superior artificial turf that performs exceptionally well in different conditions.

Fun Fact!

Did you know that artificial grass was first introduced in 1966 in the Astrodome Stadium, USA? It was originally called “AstroTurf”, and it was developed to solve the issue of maintaining real grass in indoor stadiums! Today, it’s used in countless applications worldwide.

Key Features of Aawadkrupa Plastomech’s Artificial Grass Making Machines

High-Speed Production

Fast and efficient grass manufacturing

Precision Tufting

Even fiber distribution for a natural look

Durable Construction

Long-lasting machines for continuous use

Energy-Efficient

Lower power consumption, higher savings

Customization Options

Different pile heights, colors, and densities

Automated Controls

Easy-to-use interface for smooth operation

Eco-Friendly Processing

Sustainable production with minimal waste

Applications of Artificial Grass Making Machines

The artificial turf produced using these machines finds applications in various sectors, including:

- Sports Fields: Football, cricket, tennis, and hockey grounds require high-performance synthetic turf

- Landscaping : Used in gardens, parks, and commercial spaces for a lush green aesthetic

- Residential Lawns : A perfect alternative to natural grass for low-maintenance home gardens

- Pet Areas : Provides a clean and safe surface for pets to play

- Indoor & Outdoor Décor : Ideal for event decorations, balconies, and wall coverings

Why Choose Aawadkrupa Plastomech?

Aawadkrupa Plastomech is a pioneer in manufacturing high-quality plastic processing machines, ensuring:

Consistent quality production with advanced technology

Cost-effective operation with reduced energy consumption

Customization flexibility for various turf applications

Reliable after-sales support and technical assistance

By integrating the Monofilament Extrusion Machine and Ring Twister Machine, manufacturers can produce artificial grass with superior strength, durability, and aesthetic appeal.

Conclusion

Artificial grass is revolutionizing the landscaping and sports industries, and having the right manufacturing equipment is crucial for maintaining high-quality standards. Aawadkrupa Plastomech’s Artificial Grass Making Machines are designed to meet the needs of modern synthetic turf production with efficiency, durability, and precision.

For more information about our products and services, please call us at +91 9510186014 or mail us at info@akiropes.com. Discover how we can help you revolutionize your production processes with cutting-edge extrusion technology.